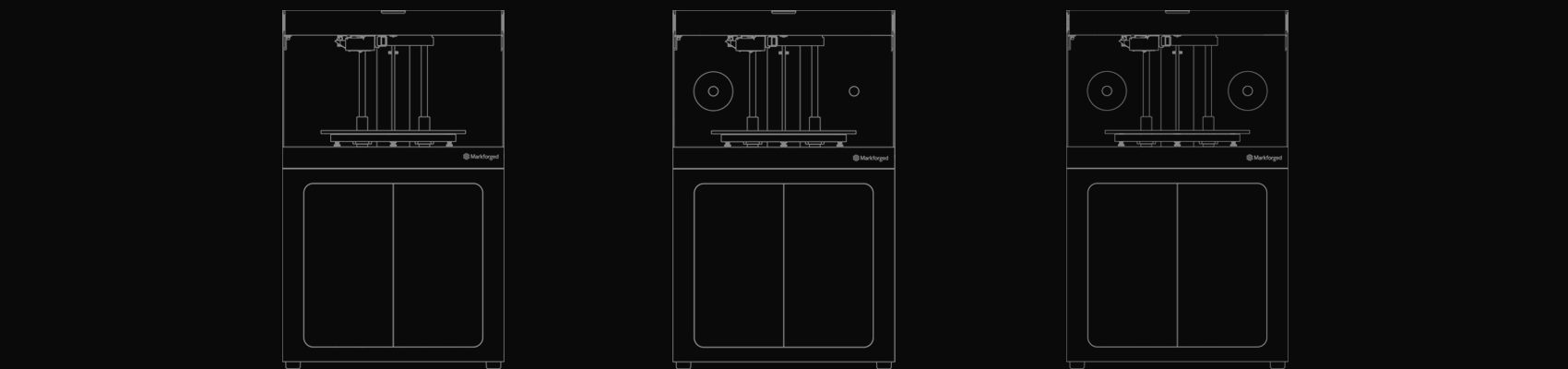

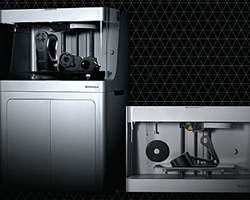

Industrial Series: The X7

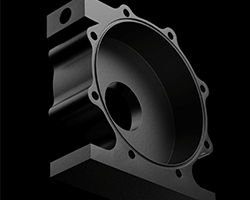

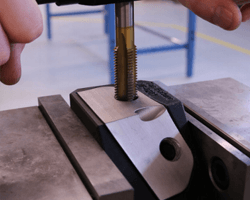

The Industrial 3D Printer for Parts Reinforced with Carbon Fiber, Kevlar or Fiberglass

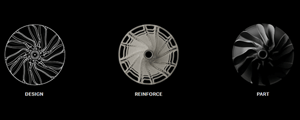

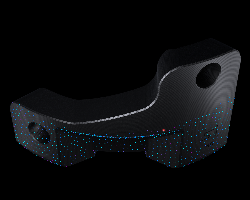

This industrial 3D printer was built for reliable performance, best-in-class quality and laser precision. The X7 takes the industrial 3D printers to the next level by introducing additional reinforcement fibers for highly durable and versatile parts that are stronger and lighter than aluminum.

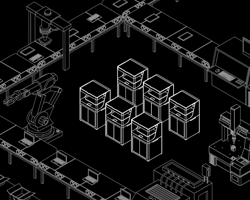

The Markforged industrial grade large-format printers are the go-to for manufacturing engineering, delivering exceptional accuracy, reliability and repeatability. The X7 can withstand the toughest applications and can be ready the same day thanks to Turbo Print mode, an X7 exclusive feature.

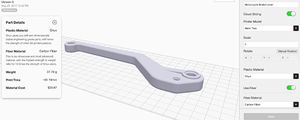

Printer Specifications:

- Adaptive Laser Bed Leveling

- In-Process Laser Inspection

- Turbo Print Mode

- Build Volume: 13 x 9.8 x 7.9 in

- Print Resolutions: 50, 100, 125, 200 and 250 Microns

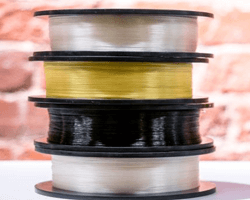

- Base Thermoplastic Materials: Onyx, Onyx FR, Nylon White

- Internal Fiber Reinforcement: Fiberglass, HSHT Fiberglass, Carbon Fiber, Kevlar

Optional:

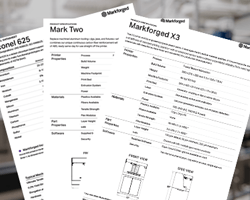

Learn more about the Markforged Industrial Series and composite 3D printing in our comprehensive online guide.